Content

- Manufacturing Costs

- Fulfill Orders More Efficiently Try Zoho Inventory Today!

- How Can Digital Manufacturing Improve Total Manufacturing Cost Management?

- Variable Overhead Costs

- Total Manufacturing Cost:

- Determine Total Manufacturing Costs

- What Is Manufacturing Overhead?

- 4 2 The Role Of The Design Engineer In Design For Manufacturability

There are many operations that can be applied to raw materials such as welding, cutting and painting. It is important to differentiate between direct materials and indirect materials. It also includes payroll taxes, insurance, workers compensation, holiday pay, and other company benefits. To figure out overhead costs, add together all factors that keep production going, both direct and indirect. Some examples of direct overhead costs include facility rent, mortgage and property taxes. Indirect overhead costs might be special oil for equipment and machinery, label printing or factory supplies.

In this case, the steel beams are physically manipulated to build the end product. To properly calculate the cost of goods sold, it’s important for manufacturing businesses to accurately calculate their manufacturing overhead rate. If your manufacturing overhead rate is low, it means that the business is using its resources efficiently and effectively. On the other hand, a higher rate may indicate a lagging production process. In addition to this, COGM contributes to the overall clarity and planning of a company. It allows the company to plan and modify the pricing strategy for its products. It gives an accurate comparison of manufacturing operations from year to year.

Manufacturing Costs

Rose Burn’s manufacturing overhead is $170,000 ($50,000 manufacturing supervisor gross pay + $60,000 factory rent + $45,000 factory utilities + $5,000 depreciation + $10,000 supplies). Rose Burn ordered its raw material from one supplier in January 2019. Enterprise Resource Planning system is software that can help you manage all of the core supply chain, manufacturing, services, financial https://www.bookstime.com/ and other processes related to your organization. It can be used to help you simplify, plan, budget, automate and accurately report on your operations. Put simply, ERP software allows you to reduce the use of unnecessary resources without sacrificing quality. Consider an example of calculating manufacturing costs for Flying Pigs Corporation and the company’s costs to make roller skates.

- At the end of the period, however, there remains only $3,000 worth of raw materials.

- Manufacturing units need factory supplies, electricity and power to sustain their operations.

- Unfortunately, it is not as simple as it seems, as each working part has multiple equations within.

- If your manufacturing overhead rate is low, it means that the business is using its resources efficiently and effectively.

- The employees or workers in the production line have to be remunerated for their services and that is why companies have elaborate payrolls that include their salaries and even retirement funds.

He graduated from Georgia Tech with a Bachelor of Mechanical Engineering and received an MBA from Columbia University. The low-cost price of a company that is traded on the stock market is an excellent competitive advantage that can increase the return on sales and investment attractiveness. Other inventory cost formula directly connected to goods buying. With rare exception, PV systems are designed to produce the lowest cost electricity consistent with achieving project objectives. At present, a PV system in the United States costs about $10–20/W installed, depending on array capacity, storage needs, utility interconnections, and other requirements. At this price, it is difficult to compete in areas where established utility service is readily available. •Use standard hole sizes and milled radii so that standard drill and milling bits can be used.

Fulfill Orders More Efficiently Try Zoho Inventory Today!

If you do things manually, with pen and paper, or spreadsheets, you will need to perform regular stock-takes and sum up all invoices for materials to get the numbers right. Once the complete realm of accountants and productivity engineers, the Total Manufacturing Cost has now been revealed as an approachable and useful tool for organizations of all sizes and types. Compensation may impact the order of which offers appear on page, but our editorial opinions and ratings are not influenced by compensation.

- The reverse approach might be attempted when unit costs are low, by setting prices lower in an attempt to attract business away from competitors.

- Whatever you do, watch out for counting costs twice by not understanding this.

- At this price, it is difficult to compete in areas where established utility service is readily available.

- The first four of these points will be dealt with in this chapter in the context of the relationship between cost, volume and profit.

- The direct labour cost is the cost of workers who can be easily identified with the unit of production.

- Additionally, it’s prudent to calculate manufacturing costs with a production timeline in mind.

Manufacturing costs include the material, labor and overhead costs. As per the total manufacturing cost amount, managers and business owners cut operational costs, improve their profitability, or lower a suggested price for customers. Consider how the total manufacturing cost affects the selling price of an item, often called the manufacturer’s suggested retail price, and our company’s profit margins. Note that it is important to include retirement funds, holiday pay, payroll taxes, or any additional fees that are incurred by paying direct labor. Some companies may also decide to include costs related to training the production staff.

How Can Digital Manufacturing Improve Total Manufacturing Cost Management?

When adding, ensure total manufacturing costs really does mean total. The sales commission on the $225 selling price is $20 per unit.

In fact, several cost-cutting mechanisms streamline the manufacturing process, leading to higher quality products and healthier books of accounts. So, while they’re not always directly considered part of the manufacturing process, these incurred costs also significantly can also impact your business’s bottom line.

Variable Overhead Costs

Total manufacturing costs are usually conflated with the costs of goods manufactured . COGM counts for the cost of inventory finished and prepared for sale in the period. Total manufacturing costs account for all costs incurred in the period, regardless of whether the product was finished. Aggregate all factory overhead costs for the period into a cost pool, and allocate the contents of this cost pool to the number of units produced during the period. Add the total cost of materials purchases in the period to the cost of beginning inventory, and subtract the cost of ending inventory. The result is the cost of direct materials incurred during the period. To get the maximum profit, the enterprise should reduce the total manufacturing cost of its products.

Consider how total manufacturing costs affect the selling price of an item, often called the manufacturer’s suggested retail price, and ultimately a company’s profit margins. Depending on the total manufacturing cost amount, managers and business owners can cut operational costs, improve profitability or lower a suggested price for consumers. Finally, you must determine the overhead costs that your company had during a production period. This could include the cost of electricity and other utilities, the depreciation of your manufacturing equipment, property taxes and insurance for the equipment and facility and other overhead expenses. Finally, a total manufacturing cost analysis might lead to a review of production processes, to see if they can be made more efficient. Doing so may reduce costs, increase product quality, and speed up the production process – which in turn may attract more customers due to the company’s reduced order turnaround times. Another advantage is that having a better understanding of total manufacturing cost allows a business to budget better for these costs in the future.

Total Manufacturing Cost:

That number is, of course, critical to setting the wholesale price of the item. Finished Goods Inventory, as the name suggests, contains any products, goods, or services that are fully ready to be delivered to customers in final form. Beginning and ending balances must also be considered, similar to Raw materials and WIP Inventory. Knowing and anticipating these changes will help you stay on top of your production costs and keep your business profitable.

- James has been writing business and finance related topics for work.chron, bizfluent.com, smallbusiness.chron.com and e-commerce websites since 2007.

- ERP/MRP software can also pre-apply the manufacturing overhead costs to your products according to an estimated rate.

- The manufacturing cost of a custom design 5MW ORC turboexpander is only $187,000 more than that of a custom design 1MW ORC turboexpander.

- Raw materials that can’t be traced to a specific product or manufacturing run are considered indirect material and are excluded from the direct material cost calculation.

- For example, the salaries for security guards, janitors, machine repairmen, plant managers, supervisors, and quality inspectors are all indirect labor costs.

- Accurately calculate all your costs so that you can make informed decisions.

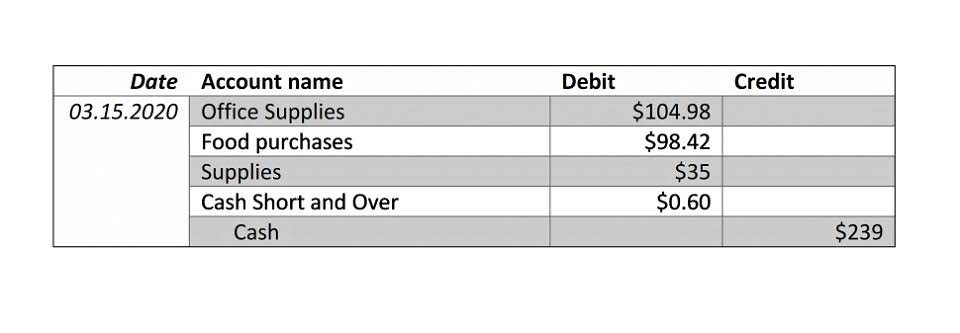

A factory’s production costs are the total expenses of doing business. The following formula is used to calculate the total manufacturing cost. We have identified our direct and indirect manufacturing costs so can apply them to the formula introduced above. To determine the total manufacturing cost amount, add together the totals from steps one, two and three. Some prominent examples are fuel and lubricants for manufacturing equipment. Like cleaning chemicals and disposable protective devices, they are consumed but do not form the final product.

Determine Total Manufacturing Costs

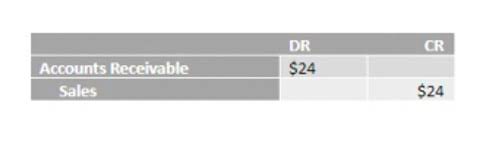

For example, a digital product like computer software may not have many direct materials but does still need direct labor and manufacturing overhead to produce. You can find the number of hours worked by each employee in the accounting period in the employee records. Multiply the number of hours worked by the employee’s hourly rate of pay to determine the labor cost for that employee.

To calculate the total manufacturing overhead cost, we need to sum up all the indirect costs involved. So the total manufacturing overhead expenses incurred by the company to produce 10,000 units of cycles is $50,000.

The cost of direct labor includes the labor, payroll taxes, and benefits of the production crew that produces goods, such as machine operators, assembly line operators, painters, and so forth. Factory overhead is the costs incurred during the manufacturing process, not including the costs of direct labor and direct materials.

What Is Manufacturing Overhead?

Total product costs can be determined by adding together the total direct materials and labor costs as well as the total manufacturing overhead costs. Manufacturing overhead is overhead directly related to the production of goods. This includes production facility rent/mortgage, utilities , indirect materials used in production, indirect labor costs related to production, maintenance costs, depreciation of equipment. Manufacturing overhead does not include administration wages, sales, marketing, office rent, or other staff salaries. Total manufacturing costs showcase how much your company spent to produce its inventory in a given period of time. This includes a thorough account of the cost of overhead, materials used, labor, and any other manufacturing expenses that contributed to completing the product. This is not to be confused with the cost of goods manufactured , which refers to just the cost of inventory that was finished and prepared for the sale in the period.

We have served countless satisfied clients in the manufacturing sector with our affordable and intuitive software. Our software would help you lower down your total manufacturing cost.

4 2 The Role Of The Design Engineer In Design For Manufacturability

These overhead costs aren’t influenced by managerial decisions and are fixed within a specified limit based on previous empirical data. They include equipment depreciation costs during manufacturing, rent of the facility, land used for inventory, and depreciation of the facility. In this example, the total production costs are $900 per month in fixed expenses plus $10 in variable expenses for each widget produced. To produce each widget, the business must purchase supplies at $10 each. After subtracting the manufacturing cost of $10, each widget makes $90 for the business. Direct materials are the raw materials that become a part of the finished product. Manufacturing adds value to raw materials by applying a chain of operations to maintain a deliverable product.

This measures the number of direct labor hours it takes to produce one unit. To calculate this, divide the number of working hours during the time period by the number of units produced. This includes raw materials, components, parts and packaging used in the production or manufacturing process of finished goods. Understanding total manufacturing costs is an important step for businesses that want to improve manufacturing productivity. These are costs in your manufacturing process that do not come from raw materials or labor primarily used in manufacturing. This includes maintenance costs, utility bills, salary of non-manufacturing staff, and MRO.

Manufacturing costs at 15% IRR rise to about $26.00 per barrel, adding an additional $12.00 per barrel to the expected minimum, or break-even, manufacturing cost. As further illustrated, this 15% IRR likely is achievable in an $18.00 per barrel crude oil market. At an 8% IRR, manufacturing costs rise to only $18.00 per barrel. However, as the illustration shows, even in a $14.00 per barrel crude oil market environment, an IRR of at least 10% should be feasible. Thus, an investment in a Fischer-Tropsch gas to liquids project is judged likely for some.

If you plan on using direct labor hours, you’ll need to calculate the total labor hours worked for the month. The same goes with machine hours if you’re planning on using that for your base calculation. Manufacturing overhead is an essential part of running a manufacturing unit. Tracking these costs and sticking to a proper budget can help you to determine just how efficiently your business is performing and help you reduce overhead costs in the future. Determining the manufacturing overhead expenses can also help you create a budget for manufacturing overhead.